Many customers do not know what properties they need to know when buying refractory bricks, and they are afraid that their questions are not professional enough and they cannot buy the right refractory bricks or other refractory materials. In fact, usually refractory bricks and other refractory materials only need to pay attention to the following six main properties to ensure that you will not buy the wrong product.

1.Refractoriness

Refractoriness is the softening temperature of refractory materials when no load is applied. The refractoriness of products mainly depends on its mineral composition, the amount of fusible impurities, the mutual bonding of minerals and the degree of diffusion of each component. The refractoriness of carbon bricks can reach above 2000℃. The amount of high melting point periclase in magnesia bricks is more than 87%, and its refractoriness can exceed 2000℃.

2.Softening temperature under load

Refractory materials are often under load pressure during use. Carbon bricks will not deform when working at high temperatures. Clay bricks have a lower load softening point, and high alumina bricks have a higher load softening temperature than clay bricks.

3.Apparent porosity

The pores of refractory materials are distributed in coarse particles, binders and between coarse particles and binders. Their existence improves the thermal insulation performance of refractory materials and reduces the corrosion resistance of refractory materials. The apparent porosity of magnesia bricks is in the range of 14% to 20%, high alumina bricks can reach 18% to 23%, and clay bricks have a higher porosity, in the range of 18% to 26%. Increasing the molding pressure and increasing the sintering temperature can reduce the porosity of the product.

4.Normal temperature compressive strength

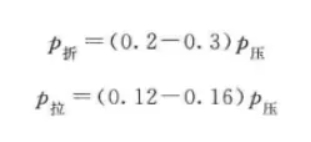

At room temperature, a pressure tester is used to load a refractory product sample of a specified size at a specified rate until the sample breaks, and the room temperature compressive strength is calculated based on the recorded maximum load and the area of the sample bearing the load. The room temperature compressive strength of refractory products is generally greater than 30MPa. The compressive strength of refractory products mainly depends on the strength of the raw material particles themselves, the firmness of the mutual bonding of the particles, the number and form of pores, and the size of the bonding ability of the added binder. The relationship between the flexural strength, tensile strength and compressive strength of refractory products is as follows:

The flexural strength decreases with the increase of pore size and porosity of refractory products. Strength changes with the increase of temperature. When heated to 1200℃, the strength of magnesia refractory material does not change much, and the strength decreases when the temperature is further increased. At 1200~1300℃, the strength of siliceous refractory material is about 85% of the strength at room temperature.

5.Re-firing line changes

The change in the reburn line is an indicator of the volume stability of the refractory material. It refers to the residual expansion or contraction that occurs when refractory products are cooled to room temperature after being kept at a specified temperature for a certain period of time. Under certain conditions, residual expansion is less harmful. Appropriate residual expansion can bridge the masonry joints and increase the life of the masonry, but excessive expansion will destroy the shape of the masonry and cause the masonry to collapse. Excessive residual shrinkage will increase the brick joints of the masonry, affect the integrity of the masonry, and even cause the gun body to collapse. The allowable reburning volume change of various refractory products generally does not exceed 0.5%~1.0%.

6.Thermal shock stability

The ability of fired refractory products to resist rapid temperature changes is called thermal shock stability, which is measured by the number of rapid cooling and heating of refractory products from 1100°C to room temperature. The thermal shock stability of refractory products is related to the thermal expansion, thermal conductivity, elastic modulus and structural strength of the products.