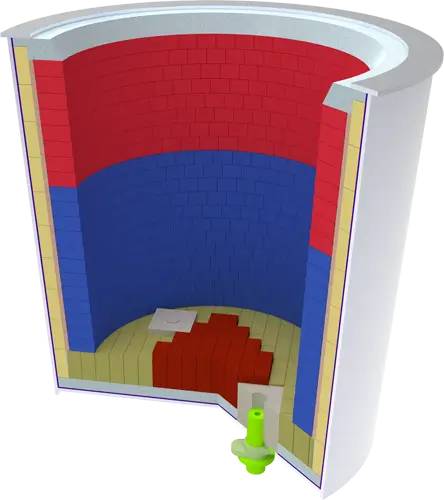

Ladle, also known as steel barrel, steel tank, big bag, etc., is a container for storing, transporting and processing molten steel. It is an important equipment for refining tasks. The ladle has two main functions: the first is to receive molten steel; the second is to perform refining outside the furnace. With the diversification of secondary refining, the consumption of refractory materials is relatively high and the service life becomes shorter. In the late 1970s, in order to reduce resource consumption and labor intensity, the method of casting refractory materials was gradually adopted in the lining of the ladle. Unshaped refractory materials are used more or less in thermal equipment and kilns in basically all industrial fields. In recent decades, ladle refractories have experienced rapid development from shaped to unshaped and then to castable. The refractory materials for ladle lining are generally divided into four parts: insulation layer refractory materials, permanent layer refractory materials, working layer refractory materials and functional refractory materials.

The refractory materials of the insulation layer play a role of insulation, and are generally lightweight insulation materials, such as: lightweight clay bricks, aluminum silicate fiberboards, lightweight coatings, lightweight porous castables, nano-reflective insulation boards, etc. The permanent layer refractory material is also called the safety layer refractory material. It mainly plays an insurance role to prevent the molten steel that leaks through after the working layer refractory material is damaged and burns the metal shell, ensuring the safety of use. The main materials of permanent layer refractory materials are: high alumina bricks, aluminum-magnesium castables, high alumina castables, etc. The refractory material of the working layer is in direct contact with the slag and molten steel in the ladle, and it must be able to withstand the high temperature erosion of the slag and the scouring of the molten steel. The service life of the ladle is determined by the mechanical scouring of the molten steel on the refractory material of the working layer and the technological level of this layer. The refractory materials of the working layer have gone through different stages such as clay bricks, high alumina bricks, wax stone bricks, carbon-free, low-carbon, and special refractory materials.

Unshaped refractory materials for ladles have always been the focus of long-term attention of the refractory materials industry at home and abroad. With the development of refractory materials, refractory materials for ladles at home and abroad have also experienced different development periods. At the beginning, ladle lining bricks abroad were mainly high-alumina bricks; in the 1970s and 1980s, medium and low-grade aluminum-magnesium-carbon (Al-Mg-C) bricks were mainly used. In recent decades, in order to reduce the consumption of refractory materials and reduce costs, many measures have been taken and achieved good results. For example, before the 1990s, ordinary Japanese ladles used relatively low-priced zircon bricks, wax stone bricks and high-silicate bricks with an SiO2 content of 85%. In the late 1990s, some Japanese ladles were constructed using the integral casting method, and to date, the usage rate of this method has accounted for about 95%. Nowadays, the main refractory material used in Japan is spinel castable, which has good resistance to slag erosion and slag penetration.

A production line of a continuous casting machine built by a foreign company had a service life of only 6 furnaces per inch of steel. After continuous testing and improvement, its service life can now reach 160 furnaces, and the operating cost has been reduced by about 40% accordingly. From the founding of the People’s Republic of China to before the reform and opening up, the domestic refractory materials for ladles were mainly aluminum silicate products. Since the 1980s, China has gradually developed a number of different types of refractory materials for ladles, including magnesium-calcium (carbon) and aluminum-magnesium (carbon). Aluminum-magnesium (carbon) refractory materials account for the majority in terms of both specifications and varieties, and have become the main refractory material for ladles in my country. Since the early 1990s, my country has successively carried out research and application of corundum-spinel castables and alumina-spinel castables, and achieved good results.

As the ladle lining material, the aluminum-magnesium refractory castable must have excellent properties such as resistance to structural spalling and corrosion. However, since it must be used for a long time in an environment above 1600℃, vitrification may occur near its working surface due to over-sintering and penetration of slag, which makes it difficult to ensure its durability. Adding a certain amount of magnesium oxide fine powder during the batching process can effectively improve some properties of alumina-magnesia spinel castables. The magnesium oxide in magnesia sand and the aluminum oxide in the material will generate in-situ spinel at high temperatures, thereby strengthening the internal organizational structure of the material, which has a good effect on improving slag resistance and inhibiting slag penetration, thereby greatly extending the service life of the ladle. Since Al2O3 and MgO react at high temperature to form in-situ spinel, the sample becomes loose and has fine structures inside, so this kind of ladle has better durability.

With the development and application of synthetic magnesia-alumina spinel materials, carbon-containing refractory materials and the progress of low-cement, ultra-low-cement and cement-free refractory castable technology, a new generation of alumina/magnesia/graphite-based refractory materials has been applied to many steelmaking containers, among which the application in ladles is the most.