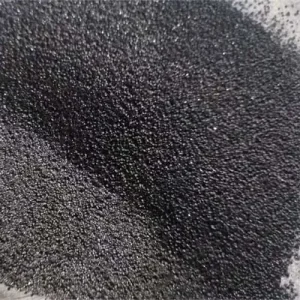

Magnesia Alumina Carbon Brick Advantages:

Magnesia Alumina carbon brick has the advantages of anti-erosion, anti-flaking, balanced erosion, safe use, less slag dipped in steel, and easy unpacking. Alumina magnesia carbon brick as the refractory lining brick is mainly used for the lining of molten steel ladle used in harsh conditions. There is an increasing number of linings in the molten pool and the bottom of the package for continuous casting of large tundish and refining packages.

Proportion Of Magnesia Alumina Carbon Brick:

In order to improve oxidation resistance, alumina magnesia carbon brick is manufactured with the additives such as Si powder, Al powder, SiC powder or ferrosilicon powder appropriately added to the ingredients and the resin as binder through high pressure molding and being treated at 200 to 300℃without calcining. Alumina magnesia carbon brick can be used for large converters and ultra high power electric furnace ladle lining and refining furnace lining, etc. It has low thermal conductivity, good isolation ability, and appropriate residual expansion.

Magnesia Alumina Carbon Brick Application:

1.Aluminum magnesium carbon brick is mainly used forsteel ladle lining;

2.Aluminum magnesium carbon brick tapping trough, large converter and ultra high power electric furnace ladle lining and refining furnace lining.

Reviews

There are no reviews yet.